Lab-grown meat, also known as cultured or cell-based meat, is revolutionizing the future of food production. This innovative technology involves growing meat directly from animal cells in a lab, without the need to raise and slaughter livestock. The promise of cultured meat goes beyond just providing a sustainable alternative to traditional meat—it holds the potential to reduce the environmental footprint of the food industry, improve animal welfare, and create more efficient methods of meat production.

As the demand for alternative proteins grows, lab-grown meat has caught the attention of startups, established food companies, and regulatory bodies. The technology is still in its early stages but has already made impressive strides, with a variety of companies around the world racing to bring these products to market.

In this blog, we will explore the global filing trends, patent landscape, market size, key players, and companies that are shaping this emerging industry.

Discover key trends and innovations in the cultivated meat market with our patent landscape sample report. Gain valuable insights into emerging technologies, market leaders, and growth opportunities. Request your free sample report today and stay ahead of the competition in this rapidly evolving industry!

1 Cell Culture – This is the most widely used technique in cultivated meat production. It involves isolating animal cells (usually muscle or fat cells) and placing them in a controlled environment, where they can grow and multiply. The cells are provided with nutrients, growth factors, and other conditions that encourage them to form muscle tissue, similar to how they would grow in an animal’s body. This process creates small amounts of cultivated meat that can be expanded and harvested for consumption.

Some of the leading patents related to the cell culture cultivated meat production technique

2 3D Bioprinting – 3D bioprinting is a cutting-edge technology that uses a printer to layer bio-inks containing cells, growth factors, and scaffolding materials to build up complex tissue structures layer by layer. The technique allows for more precise control over the texture, shape, and size of the cultivated meat, mimicking the natural structure of muscle and fat tissues found in real meat. This method can potentially improve the sensory qualities (like taste and texture) of cultivated meat.

Some of the leading patents related to the 3D Bioprinting technique

3 Scaffold-based Techniques – Scaffold-based techniques use a framework, or scaffold, to support the growth and alignment of cells into the desired tissue structure. These scaffolds can be made from natural or synthetic materials, which provide mechanical support and help cells organize themselves into muscle fibers. As the cells grow, they develop into a larger, cohesive piece of meat. Scaffolding helps replicate the natural texture and structure of meat, improving the final product’s mouthfeel and consistency.

Some of the leading patents related to the Scaffold-based technique

4 Bioreactor-based Cultivation – Bioreactors are vessels where cells are cultured under controlled conditions for large-scale meat production. These reactors provide the optimal environment for cell growth by regulating factors like temperature, pH, oxygen levels, and nutrient supply. The bioreactor-based approach can be used in conjunction with other techniques like scaffold-based methods or microcarrier-based cultivation to create larger quantities of cultivated meat. It allows for the cultivation of tissue over longer periods, ensuring that the meat grows in a controlled and efficient manner.

Some of the leading patents related to the Bioreactor-based cultivation

5 Tissue Engineering – Tissue engineering combines biological cells with engineering techniques to grow tissues that mimic natural muscle or fat. This method often involves growing muscle fibers and connective tissues together to create meat-like structures. The process includes manipulating cells to grow into desired shapes and structures, possibly using scaffolds or bioreactors to encourage the right tissue development. The goal of tissue engineering is to produce meat that closely resembles the texture and composition of traditional meat.

Some of the leading patents related to the Tissue engineering

6 Synthetic Biology – Synthetic biology is an emerging field that applies engineering principles to biology. In cultivated meat production, synthetic biology involves genetically modifying cells to optimize them for meat production. For example, scientists may alter cells to improve growth rates, enhance fat content, or increase muscle development. This approach could potentially improve the efficiency and sustainability of the meat production process by enabling cells to grow faster or produce a more desirable composition of tissue.

7 Microcarrier-based Cultivation – In this technique, animal cells are cultured on small, spherical beads called microcarriers. These microcarriers provide a surface for cells to attach and grow, allowing for high-density cell proliferation. This method is commonly used in large-scale bioreactors where the cells grow in suspension, with microcarriers helping to support the growth of the cells and providing a 3D structure for tissue development. This method can improve scalability and cost-effectiveness in the production of cultivated meat.

The global cultured meat market is estimated at ~ USD 250 million in 2023 and is projected to reach ~ USD 1.5 billion by 2030, at a CAGR of ~30% from 2023 to 2030.

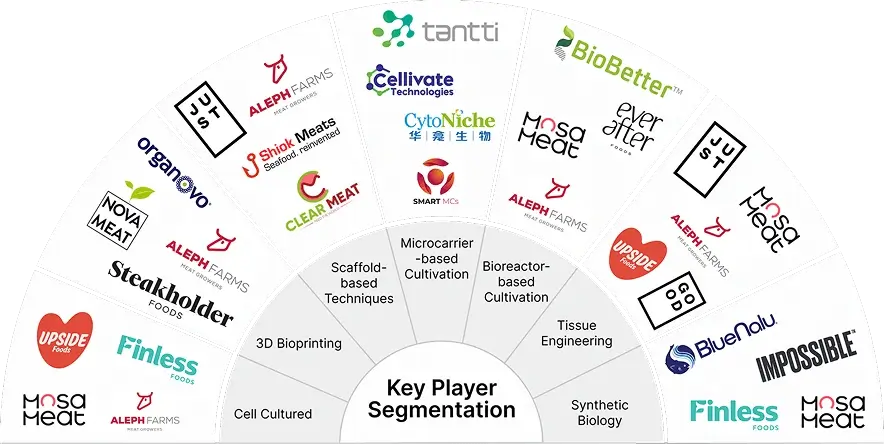

Key Player Segmentation

Cultured meat is a promising domain with potential to reach ~ USD 1.5 billion market evaluation growing at a CAGR of ~ 30% from 2023 to 2030. This article is just an overview about what’s happeing in the domain right now for in-depth insights you can get in touch with our subject matter experts today.

For more than a decade, we have been offering top notch intellectual property (IP), technology, and market research service to our global clients, including Fortune 500 companies, small enterprises, and onshore IP law firms.

Services:

Schedule a one-on-one meeting with our subject matter experts and discuss your project queries today!