The growing concern over plastic waste and its environmental impact has led to a significant shift towards sustainable materials in various industries, particularly in medical packaging. Bioplastics, derived from renewable biomass sources, are emerging as a viable alternative to traditional petroleum-based plastics in the medical sector.

They play a crucial role in addressing the challenges associated with medical waste. Many medical devices and packaging materials are single-use, which poses a significant disposal problem due to contamination that prevents recycling. Moreover, bioplastics can be engineered to meet stringent sterility standards for patient safety and device efficacy. This makes them suitable for a wide range of applications, including disposable syringes, surgical trays, and personal protective equipment (PPE).

As the medical industry continues to innovate and prioritize sustainability, bioplastics represent a forward-thinking approach to enhance patient care and contribute to a healthier planet. This post will focus on leading companies, their products, recent advancements, and strategic initiatives in the bioplastic sector impacting the medical field.

So, scroll on for some thought-provoking insights on the bioplastic in medical sector.

As the medical industry increasingly prioritizes sustainability, several leading companies are stepping up to provide innovative bioplastic solutions that address environmental concerns while maintaining safety and efficacy in healthcare applications. These companies are developing bioplastics derived from renewable resources, which not only reduce carbon footprints but also meet stringent regulatory standards essential for medical use.

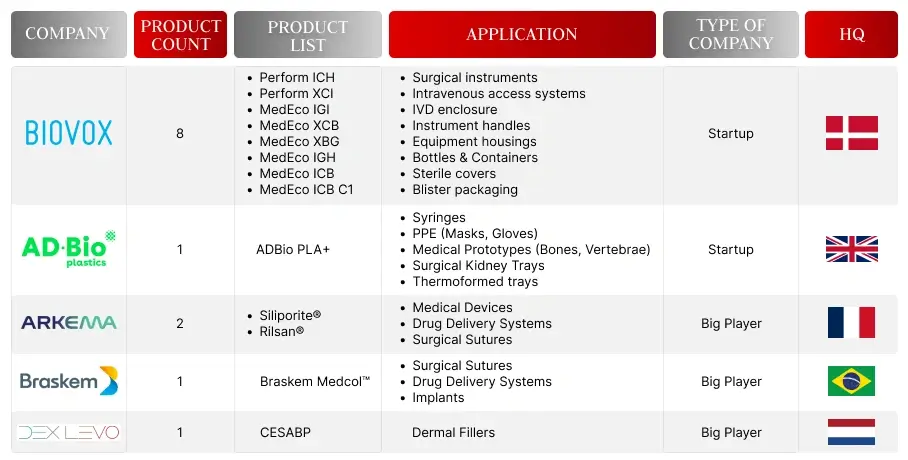

Below are some of the well-known players in the bioplastic sector and their notable products aimed at revolutionizing medical applications.

BIOVOX GmbH, founded in 2021, is dedicated to pioneering sustainable medical-grade bioplastics. The company focuses on reducing the environmental impact of healthcare products, addressing the significant carbon footprint associated with conventional plastics. Using renewable raw materials, BIOVOX’s bioplastics provide a safe and effective alternative for various medical applications. BIOVOX offers three major medical-grade bioplastics for the medical and laboratory sectors to reduce the carbon footprint.

MedEco bio-compounds are used in medical and laboratory equipment and packaging. They have a reduced environmental impact compared to fossil plastics, making them essential for a sustainable circular economy.

MedEco Product Lineup Includes;

• MedEco RIGID

• MedEco SOFT

• MedEco PERFORM

ICB and ICB C1 medical bioplastic materials are ideal for manufacturing transparent medical products that require high surface hardness and rigidity. Its application includes:

• Wellplates

• Surgical instruments

• Intravenous access systems

MedEco IGH medical bioplastic material is ideal for manufacturing medical products that require a grip-friendly, heat-resistant, and rigid material. Its application includes:

• IVD enclosure

• Instrument handles

• Equipment housings

MedEco XCB and XBG medical grade bioplastic materials can be used to manufacture products with high stiffness and surface hardness. Ideal applications in the medical sector include:

• Bottles & Containers

• Sterile covers

• Blister packaging

BIOVOX has yet to provide detailed information about MedEco IGI on its official website. However, the new medical-grade material can be used to manufacture products requiring temperature resistance.

There are two medical grade materials under this category – Perform ICH & Perform XCI.

Perform ICH can be used to manufacture products that require an impact-resistant, crystal-clear material with high temperature resistance. Its application includes:

• Respiratory equipment

• Very durable device components

• Optical components

While, Perform XCI can be used in products that require a crystal clear, heat-resistant material with high impact strength, such as:

• Containers

• Equipment housings

• Plates

ADBioplastics is a Valencian startup focused on developing and manufacturing innovative bioplastics and additives aimed at enhancing the mechanical properties of virgin polylactic acid (PLA).

ADBio PLA+ is a biobased and compostable multifunctional additive designed to enhance the mechanical properties of virgin polylactic acid (PLA). Developed by ADBioplastics, this additive improves impact resistance and toughness, achieving up to seven times greater elongation at break compared to standard PLA.

The company uses various molding, extrusion, and 3D printing technologies to manufacture various medical equipment such as Disposable medical devices (syringes), PPE (masks, gloves, Medical prototypes (bones, vertebrae), Thermoformed trays, Surgical kidney trays, and Orthotic products (treatment of injuries, disabilities)

Arkema S.A. is a global leader in specialty materials, headquartered in Colombes, France. Established in 2004 as part of Total’s restructuring of its chemicals business, the company operates across various sectors, focusing on innovative and sustainable materials to meet the challenges of modern society.

Siliporite® is a specialized adsorbent material designed for the pharmaceutical industry, particularly for moisture control and purification applications. These beads are characterized by their high porosity and large surface area, making them effective in capturing and retaining moisture, odors, and volatile organic compounds (VOCs) that can compromise the integrity of pharmaceutical products. Thereby enhancing product safety and reliability for consumers.

Rilsan® a high-performance bio-sourced polyamide derived from castor oil which is used in various medical applications due to its excellent biocompatibility and mechanical properties. It is suitable for manufacturing medical devices, surgical sutures, and drug delivery systems, providing a renewable alternative to traditional petroleum-based plastics.

Ecompo is a company specializing in the development and production of biodegradable and compostable materials, primarily focusing on bioplastics. Founded with a commitment to sustainability, Ecompo aims to provide eco-friendly alternatives to conventional plastics, helping to reduce environmental impact and promote a circular economy.

NonOilen® is a compostable bioplastic designed for environmentally friendly applications, particularly in the medical industry. This innovative material is notable for its ability to decompose in industrial composting facilities, making it an ideal choice for single-use medical products such as syringes, packaging, and other disposable items.

Braskem S.A. is a leading global petrochemical company, recognized as the largest producer of thermoplastic resins in the Americas and a pioneer in biopolymer production. Established in 2002 through the merger of six companies from the Odebrecht Group and the Mariani Group, Braskem has grown to become a key player in the chemical industry with a strong commitment to sustainability.

Braskem Medcol™ is a bioplastic material that has gained attention for its applications in the medical sector, particularly in developing biodegradable and biocompatible products. This innovative material is designed to meet the stringent requirements of medical applications, such as surgical sutures, implants, and drug delivery systems.

Pierre Fabre, a French pharmaceutical and cosmetics company has collaborated with Sorbonne University to develop biodegradable bioplastics derived from microalgae. This initiative aims to create materials that capture CO2 and can be used in packaging, contributing to sustainability in the industry. The company plans to launch its first industrial batches of this bioplastic by 2030 and explore other sustainable packaging options.

Ambu has received FDA clearance for its Ambu® aScope™ Gastro Large, a therapeutic gastroscope designed for upper gastrointestinal (GI) procedures featuring a 4.2 mm working channel and a bioplastic handle. This new addition expands Ambu’s single-use portfolio, enabling physicians to address a broader range of needs in various hospital settings, including the ICU and operating room.

Sulzer Launches CAPSUL™ for Continuous Manufacturing of Biodegradable PCL

Sulzer introduced CAPSUL™, a new end-to-end licensed technology for continuously manufacturing polycaprolactone (PCL), a biodegradable polyester. Its key applications include consumer packaging, 3D printing, footwear, agricultural films, textiles, and medical devices.

Dexlevo has pioneered CESABP (Collagenesis-Enabled Solubilized Active and Biodegradable Polymer) Technology, a groundbreaking invention in bioplastics aimed at enhancing dermal fillers. Traditional fillers, particularly those based on hyaluronic acid, degrade quickly in the body, leading to short-lived results. In response, Dexlevo developed a fully solubilized form of polycaprolactone (PCL), which overcomes the limitations of existing bioplastics.

This innovative material allows for smoother injections, better distribution within the skin, and the stimulation of collagen production. The result is a safer, long-lasting filler that improves skin thickness, density, and elasticity without the risk of lumps.

With patents secured in South Korea, the U.S (US20190358363A1) and internationally, CESABP represents a significant advancement in the field of bioplastic technology for cosmetic applications.

BIOVOX has successfully closed a €2.2 million seed funding round led by High-Tech Gründerfonds with contributions from Beteiligungs-Managementgesellschaft Hessen mbH and various private investors. This funding will accelerate the development and production of their innovative bioplastic solutions aimed at reducing the healthcare sector’s carbon emissions.

Floreon has secured a £250 million investment from the Centre for Process Innovation (CPI). Floreon specializes in proprietary compounds made from polylactic acid (PLA) bioresin, utilizing 70% to 90% renewable materials like corn and sugar cane. The CPI investment will enable Floreon to scale its technology, furthering its mission to transform the plastics industry by providing sustainable alternatives.

In conclusion, the shift towards bioplastics in the medical industry signifies a crucial step towards sustainable healthcare solutions, effectively addressing the challenges of plastic waste while meeting stringent safety standards. As innovations continue to emerge, bioplastics are set to play an increasingly vital role in enhancing patient care and promoting environmental responsibility.

For an in-depth report on the impact and future of bioplastics in the medical sector, get in touch with our experts today!